Coventry Datacentre – Build Completion

We have been working closely with our contractors in an effort to expedite the completion of our new Coventry Datacentre, and with our testing now also finally complete we are able to bring customer’s servers online within the new state-of-the-art Datahall housed within. Over the coming months, we will provide you with a number of articles that detail the cooling, power infrastructure and networking at the site however this update gives a general update of how the site now looks.

What does it look like now?

Since the last update the site has been transformed with over 300 racks installed, hot/cold aisle containment and power distribution to all racks now fully completed . Our raised flooring has been installed with grilles for cold air supply to the racks and ample ventilation at the top for hot aisles to allow for a natural cold-to-hot airflow throughout the hall.

Fire suppression systems have been commissioned using IG-541; a mixture of inert gases to keep the server equipment safe. The electrical supply has been spaced underneath the raised flooring and distribution boards provide us with greater control over incoming power for maximum redundancy and safety.

The site is fed by two high-voltage supplies from the local network operator. Behind this sits our three cast resin transformers, providing redundant power to our electrical switchgear and UPS systems. Three rooms house this equipment, each of them fire rated with the utmost safety to our personnel and redundancy in mind. They are colour coded for ease of reference: Red, Blue and Grey providing “A/B + C” distribution to the APCs within the individual racks, ready for our clients to use.

Backup power to the site is provided by three diesel 1.2MW generators, positioning these onsite was quite a complex operation with very little space in and around the site to lift these in as shown in the video below.

What about the servers?

We continue to primarily use Supermicro equipment in our datacentre, the new racks we are using onsite are slightly longer than our existing facility at 1200mm allowing for additional room for cable management. Given the current situation with energy supply and pricing we are ever conscious of the need to improve our energy efficiency through the use of more power efficient multinode chassis servers, hot and cold aisle containment and the use of indirect free air cooling.

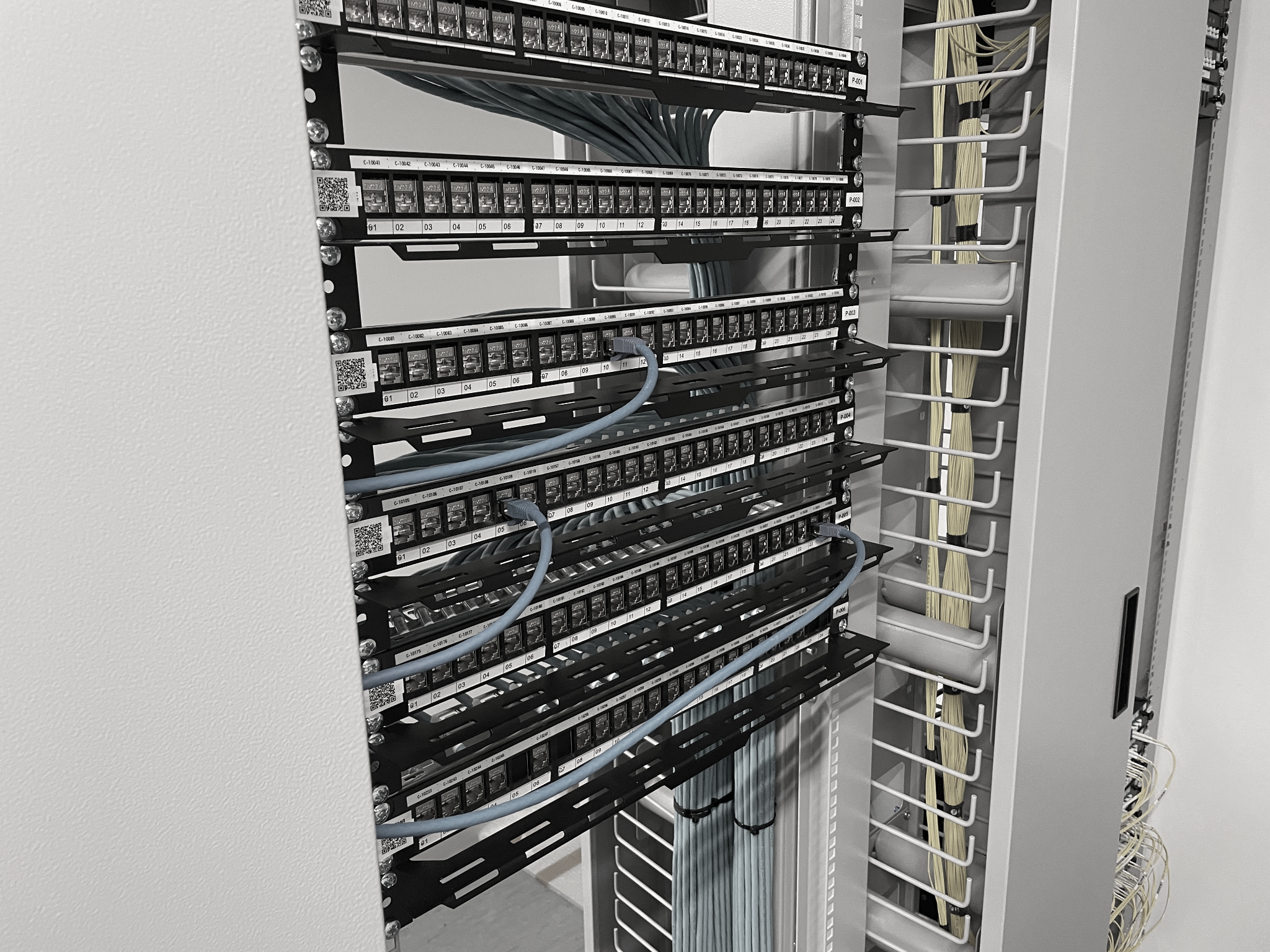

And the network?

The site is now fully connected to our UK MPLS network with multiple diverse 100Gb/s connections into the site we can offer 10Gb/s connections to customers servers and upto 200Gb/s DDoS mitigation using our own inhouse Corero filtering devices.